Predictive maintenance with IoT: The road to real returns

The Internet of Things is having a big effect on the maintenance sector, leading to increased automation, more efficient operations, and the creation of valuable new business models. While the application of digital technologies can bring benefits across the value-chain, it is arguably in the area of predictive maintenance that the most significant impact can be derived.

Use of sensors.

The use of sensors and data analysis means companies can spot patterns in equipment condition and performance, and accurately predict when a failure might occur. Such foresight eliminates unplanned downtime, delivering substantial productivity benefits.

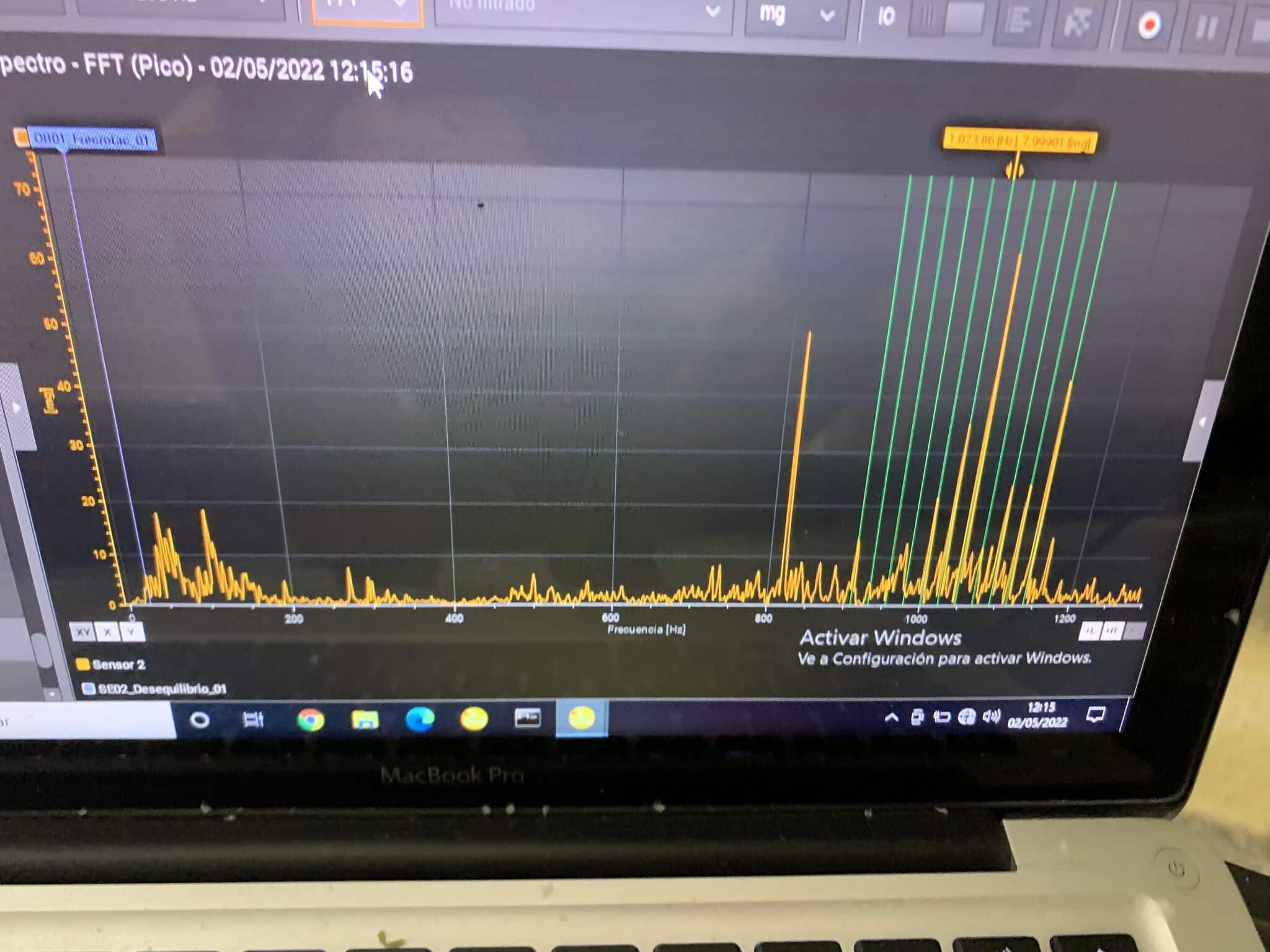

-See the pictures

Predictive Maintenance is a proactive technological method that tracks servomotors in real time and predicts servomotor failure so that your company can fix it before it causes any downtime.

This picture is a clear example. Predictive maintenance with IoT: The road to real returns

And in this way, it dynamically monitors processes, detecting potential future faults and regulating them before they have any consequences.

There are many factors that contribute to equipment condition, from age to operating environment, to past maintenance schedules, and even quality of repair.

The problem? The lifecycle of equipment can vary dramatically based on these factors, yet you won’t know how much until it’s too late.

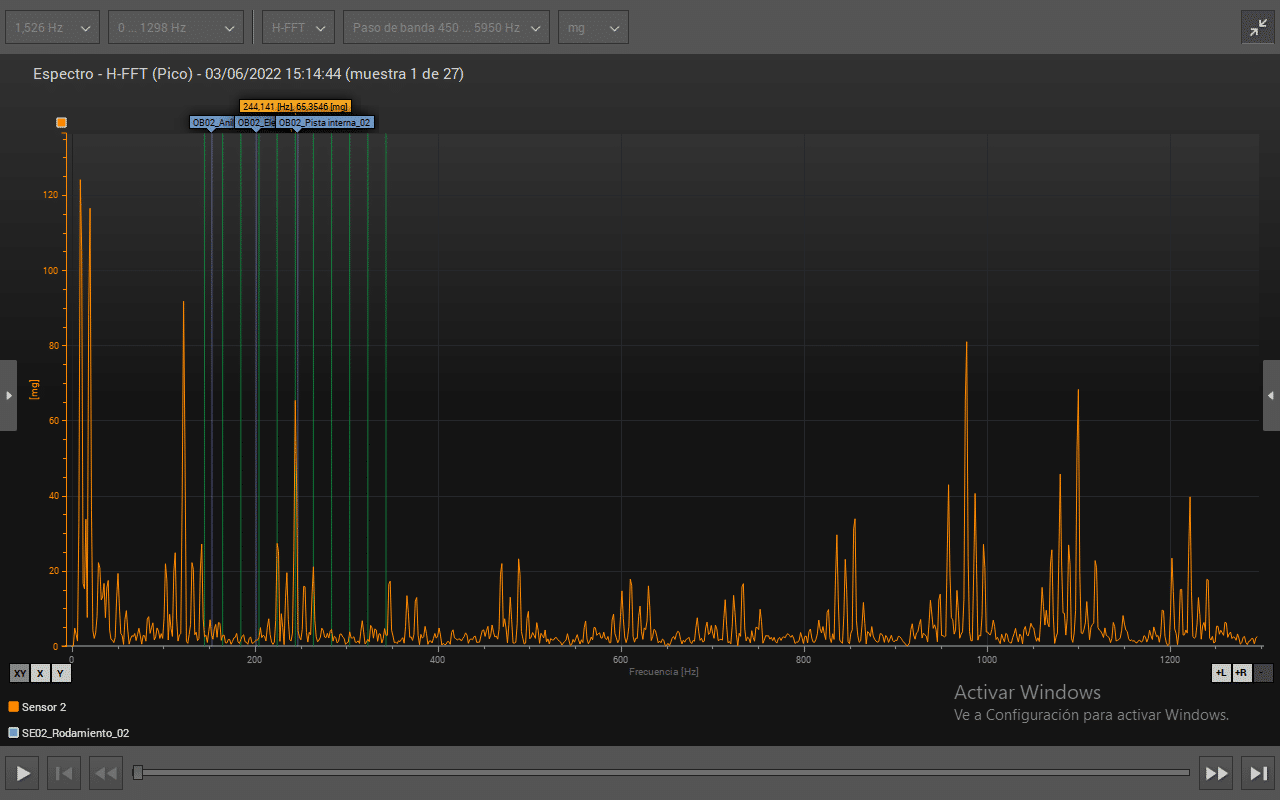

Implementing this type of predictive maintenance strategy requires a thorough understanding of how and why servomotors fail, as well as early detection of potential problems or failures.

This picture is a clear example of the importance of understanding why things happen.

-See the pictures

What do you think about the advantages of IoT?

Predictive maintenance offers many benefits, from reduced downtime and fewer productivity lags to cost-savings advantages.

Additionally, an important advantage is the possibility of analyzing servomotors difficult to access.

- At Servo Motors Adjust we are immersed in a connected era, in which the Internet of Things (IoT) is beginning to play a fundamental role:

IoT facilitates digital transformation, optimizes processes, and allows us to be more agile, efficient, and more productive.