Advanced Repair of Schneider Electric ILM Servomotors: Precision, Traceability and Commitment to the Circular Economy

At Servo Motors Adjust, we recently completed a batch of Schneider Electric ILM servomotors—compact, high-performance units widely used across automated production lines. Thanks to their integrated design, combining motor, drive electronics, encoder and brake in a single housing, ILM servomotors deliver impressive performance for packaging, labelling, handling, dosing and any application requiring tight synchronisation.

But this same compactness is precisely what makes them complex to repair. The slightest mechanical deviation, thermal issue or encoder drift can compromise system accuracy. Our workshop therefore applies a high-precision process to every ILM repair, ensuring reliability, compliance with OEM requirements and full traceability.

Below is an overview of the key interventions carried out during each repair campaign.

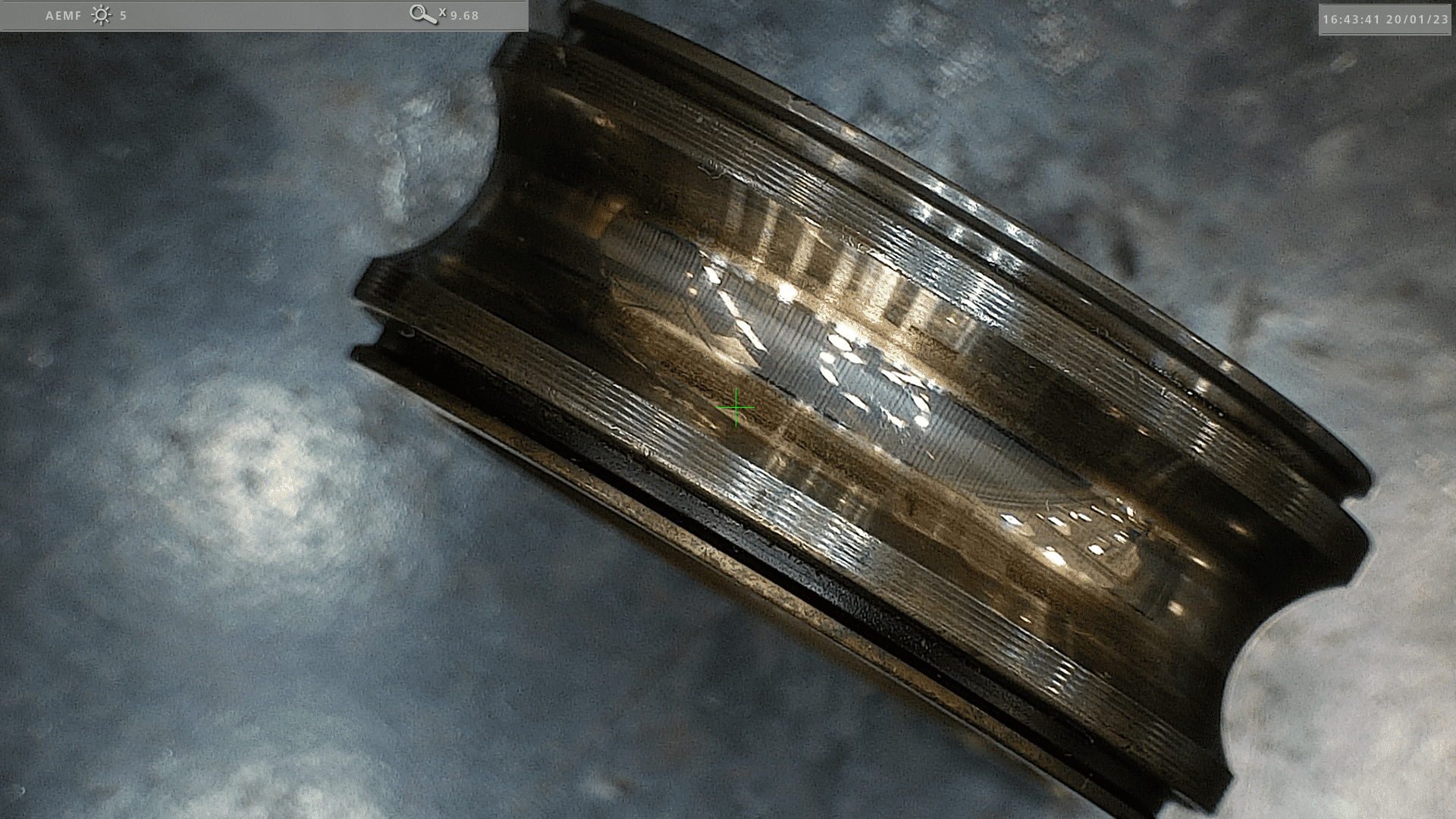

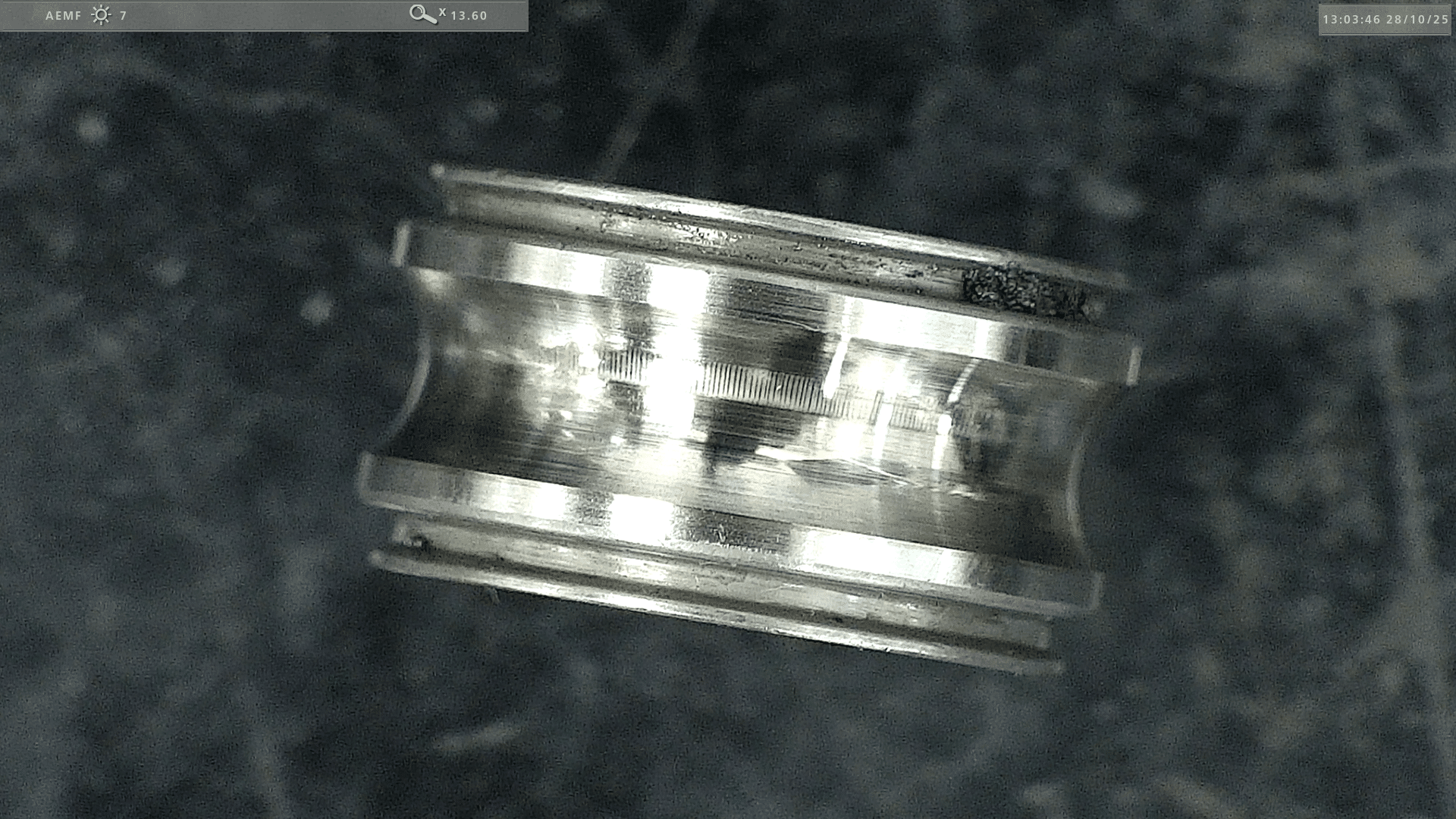

1. Bearing Replacement and Failure Diagnosis

Bearing degradation is one of the most common causes of failure in ILM servomotors. The root causes are often linked to:

-

Excessive or incorrect radial loads

-

Thermal stress and overheating

-

Environmental contamination

-

Mounting misalignment

We install new bearings, verify tolerances and internal clearances, and inspect seating surfaces to eliminate unwanted vibrations and mechanical noise.

In an integrated drive motor, the bearing is not just a mechanical component—it directly influences encoder precision, rotor alignment and overall control accuracy. Ensuring proper bearing performance is therefore critical for restoring the servomotor’s full capabilities.

2. Replacement and Programming of Stegmann SKS36 Hiperface Encoders

Several ILM units arrived with encoder faults requiring the installation of new Stegmann SKS36 encoders. These encoders contain essential data:

-

Calibration parameters

-

Mechanical and electrical alignment values

-

Motor identification

-

Absolute position information

Installing a new encoder is only half the job. It must be correctly programmed so the Schneider Electric servo drive recognises it and maintains perfect system synchronisation.

Using original OEM tools, we perform:

✔️ extraction of parameters from the faulty encoder

✔️ transfer of data to the new encoder

✔️ precise mechanical alignment of encoder and rotor

✔️ closed-loop validation with the motor’s own driver

This ensures seamless reintegration into the customer’s machine, with no loss of accuracy or synchronisation.

3. Dynamic Rotor Balancing

Vibration is one of the main enemies of servomotor longevity.

For ILM motors—often used in applications with frequent start-stop cycles and high accelerations—dynamic rotor balancing is indispensable.

Our process ensures that:

-

The rotor runs with minimal vibration

-

Encoder readings remain precise

-

Bearings are subjected to reduced mechanical stress

The result is a smoother, more reliable motor capable of withstanding heavy-duty dynamic cycles.

4. Full Validation of Integrated Electronics

Each ILM motor contains drive electronics built directly into the housing. After repairs, our technicians conduct a full inspection and test of these electronics:

-

power stage behaviour

-

signal integrity

-

thermal response

-

communication and sensor channels

Ensuring electronics integrity is essential before moving to final testing.

5. Final Test with Schneider Electric Driver

An ILM servomotor is not considered repaired until it passes a full functional test with its own driver. On our dedicated test bench, we verify:

-

Encoder feedback accuracy and resolution

-

Stability of the control loop

-

Dynamic response and torque behaviour

-

Temperature rise and thermal stability

-

Vibration measurements.

Only motors that pass all tests are certified, documented and returned to the customer with a full warranty.

Repairing Instead of Replacing: A Real Contribution to the Circular Economy

Each repaired servomotor avoids the environmental and economic cost of replacing a complex electromechanical unit. By extending product life, reducing waste and preserving the value of existing equipment, our repair process directly supports the principles of the circular economy.

For our clients, this means:

-

Lower maintenance costs

-

Shorter lead times compared with new equipment

-

Reduced carbon footprint

-

Reliable, OEM-compatible performance

At Servo Motors Adjust, we are proud to contribute to more sustainable and resilient industrial operations—one servomotor at a time.