How to prevent oil and grease from entering a robot’s servomotor.

In the repairs of robots’ servomotors there is a type of failure that happens very often – the entry of oil into the motor coming from the gearbox (see pictures 1 and 2). This directly affects crucial parts necessary for the proper functioning of the motor:

The brake: The oil invades its mechanical parts preventing it from working properly. This means that the robot’s arm is not able to lift heavy weights and this can cause

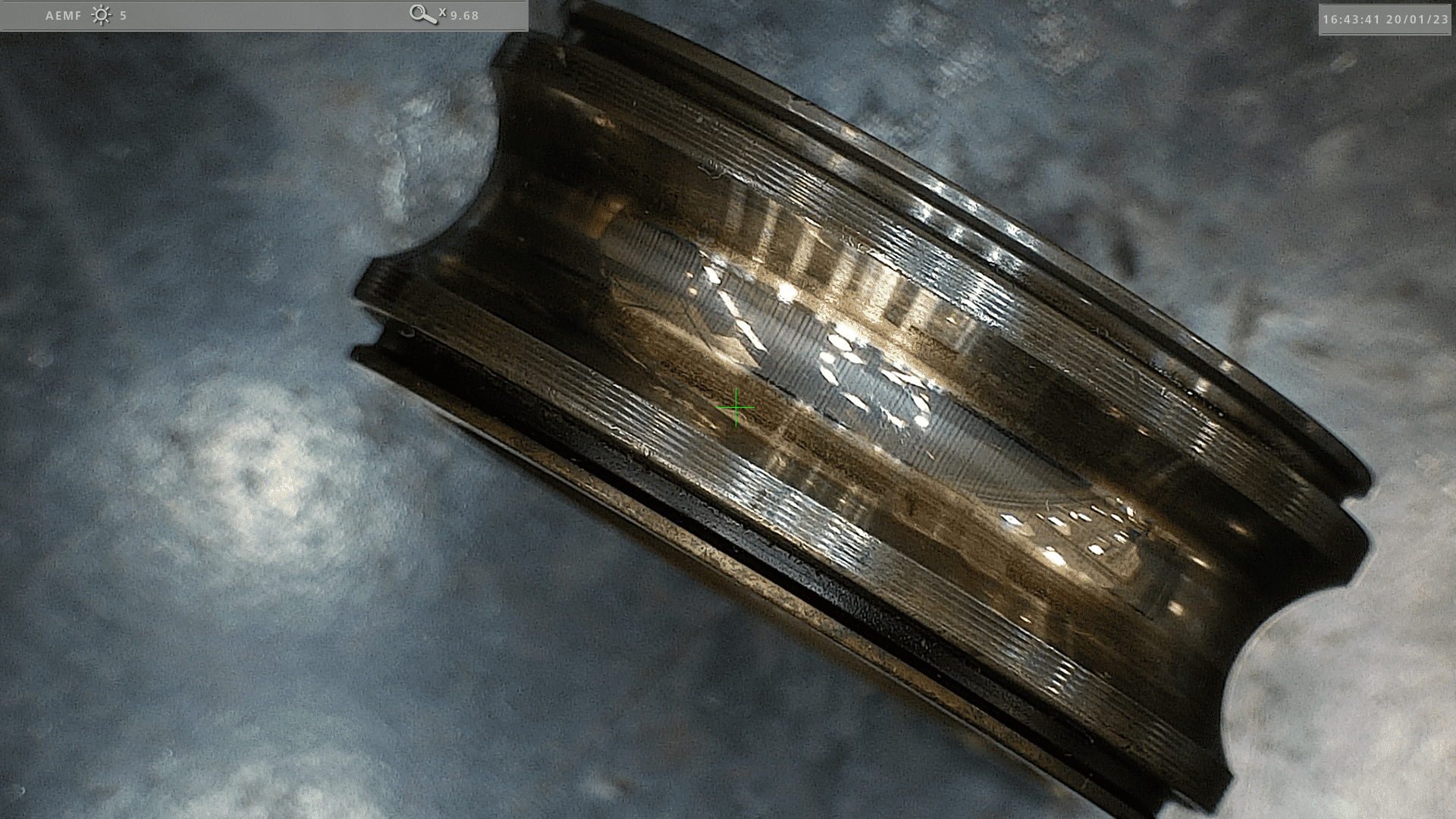

Picture 1: The grease invades the space between the brake coil and pressure plate preventing the brake from working properly

Picture 2: the robot’s servomotor’s brake covered with grease.

Causes of oil ingress in a Servomotor

There are two main causes:

- Too much grease in the gearbox can lead to these failures.

- The servomotors’ oil seal is another reason why this can happen. With the passing of time the seal loses its properties and part of its effectiveness.

The solution to avoid these failures is to plan and carry out a good preventive maintenance of your motors.

As a preventive measure we recommend this maintenance every 5 or 6 years depending on the servomotor’s working life.

In this kind of maintenance it is necessary to do the following tasks:

- Change the oil seal

- Change the bearings.

- Check the shaft (alignment, bearings’ casing and state of the magnets).

- Check the covers: front and rear.

- Check thoroughly the servomotor’s stator.

- Clean all the components.

- Check the power and signal connectors.

- Verify the feedback.

Another important point you need to take into account is to add the manufacturer’s recommended amount of oil or grease to the gearbox, although sometimes it does not seem to be enough.

Following these tips you can be sure that this kind of failures will be considerably reduced. In addition, you will prevent unscheduled downtime and costly repairs.