What is a resolver?

A resolver is an analog rotary position sensor, which can regulate speed, position or torque through digital impulses.

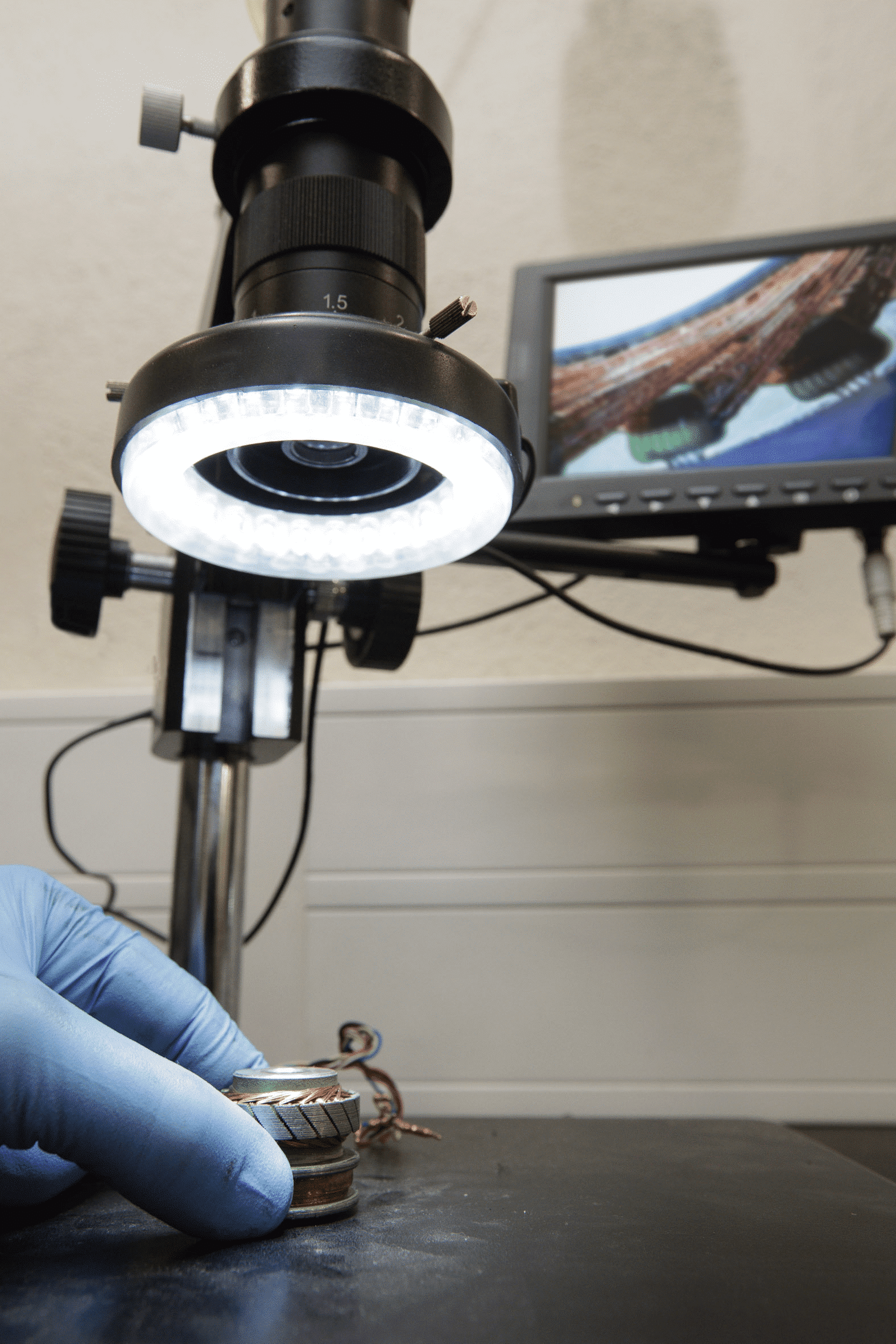

The resolver consists of a stationary part called a stator and a rotating part called a rotor, which is mounted on the motor shaft.

How does a resolver work?

The primary stator winding is connected to a high-frequency sinusoidal signal. This signal is transmitted to the rotor winding because the primary stator winding and the rotor winding act together as a transformer. Furthermore, we can also call the rotor winding the reference winding.

The pulsating alternating magnetic field of the rotor winding now induces an alternating voltage in the sine and cosine measurement windings. Their amplitudes, however, depend on the angular position of the rotor.

If the rotor winding and the measurement winding are parallel to each other, the magnetic rotor’s field passes completely through the measurement coil and therefore the induced voltage is maximum.

However, if the rotor winding and the measurement winding are at right angles to each other, no voltage will be produced.

There are 1, 2, 3, 4, etc. speed resolvers. That is to say, 1 speed is 360 electrical degrees of a mechanical turn:

For a 1-speed resolver, 360 electrical degrees will be 360 mechanical degrees. For a 2-speed resolver, 360 electrical degrees will be 180 mechanical degrees. This ratio of mechanical and electrical degrees will be the same for 3, 4 or 5 speeds, etc.

A resolver is made up of the following wiring with its corresponding function:

- Excitation: +exc / -exc

- Cosine: +cos /-cos

- Sine: +sen / -sen

It is important to compare the transformation ratio, the input voltage and the current consumption with the specifications of your control unit. Higher current consumption implies less sensitivity to electromagnetic interference.

The control unit that is used in a certain brand of servomotor is not necessarily compatible with any kind of resolver.

The main applications of resolvers can be:

Resolvers are used in servomotors in different industrial sectors (robotics, automotive, packaging, food and beverage, etc …) in which electrically powered machines are used for defined processes. Since they are robust and reliable feedback systems that precisely control a servomotor’s speed.

Some of the advantages of using a resolver are:

- The resolver itself does not contain electronic components and therefore can withstand hot temperatures as high as 175°C and cold temperatures as low as -55°C

A resolver is the ideal reliable feedback device for use in adverse environmental conditions, since there is no electrical or mechanical connection between the rotor and the stator.

- The resolver rotor is mounted directly on the motor shaft, giving a robust measurement system for speed and position signals.

- It can also reach a speed of 90,000 rpm.

- The resolvers are not susceptible to dirt, oil or hot environments since the electronic circuits are in other devices. Devices like encoders are more susceptible to these conditions. Therefore, resolvers have been the feedback device of choice for many manufacturers.

Main problems of resolvers: Short circuit of the excitation coil or the output signal coils.

Possible errors that may appear:

- Do the frequency, input voltage, transformation ratio and current consumption values of the resolver match the predefined values in the control unit?

- Is the wiring between the resolver and the control unit correct?

- Are the rotor and stator of the resolver properly aligned?

- Are there electromagnetic interferences (electric motor brake, long control cables in a room full of motors)?

Solution:

- Twist the wires (input voltage, sine, cosine)

- Shield the cables

- Disrupt the magnetic flux using a non-magnetic resolver

- It is important to know if the mechanics of a standard resolver is not compatible with the motor used or if the electrical characteristics do not match the control unit. It is necessary to know the control unit’s technical sheet to identify the type of resolver that is needed.