Why a servomotor shaft can break?

A servomotor shaft can break due to a variety of mechanical, operational, or installation-related causes. Below are the most common reasons, categorized for clarity:

1. Mechanical Overload

-

Excessive torque beyond design limits can shear the shaft.

-

Sudden impact loads (e.g., emergency stops or collisions in CNC machines).

-

Repeated shock loading or high-inertia starts/stops without proper ramping.

2. Misalignment

-

Misalignment between the motor shaft and the driven load (e.g., gear, coupling, pulley) causes:

-

Uneven stress distribution

-

Shaft bending or fatigue over time

-

-

Common in poor mounting or incorrect installation practices.

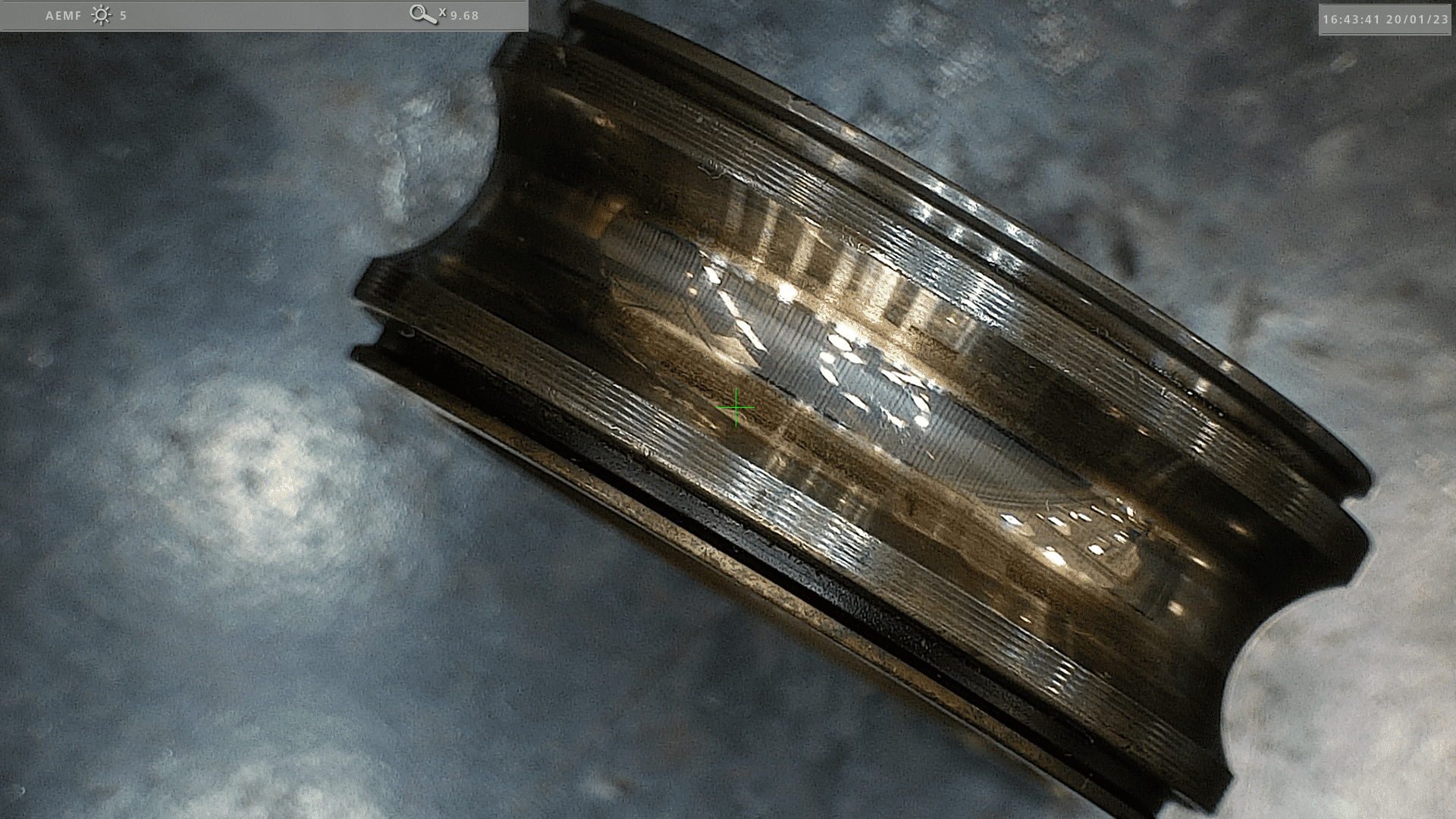

3. Fatigue Failure

-

Cyclic stress over time, even if below yield strength, can cause crack initiation.

-

Common in applications with frequent reversals or load fluctuations.

-

Stress concentration points, such as keyways or sharp corners, accelerate fatigue.

4. Improper Coupling

-

Using rigid couplings in applications needing flexible ones transmits undue stress to the shaft.

-

Misuse of couplings that don’t accommodate slight misalignments or thermal expansion.

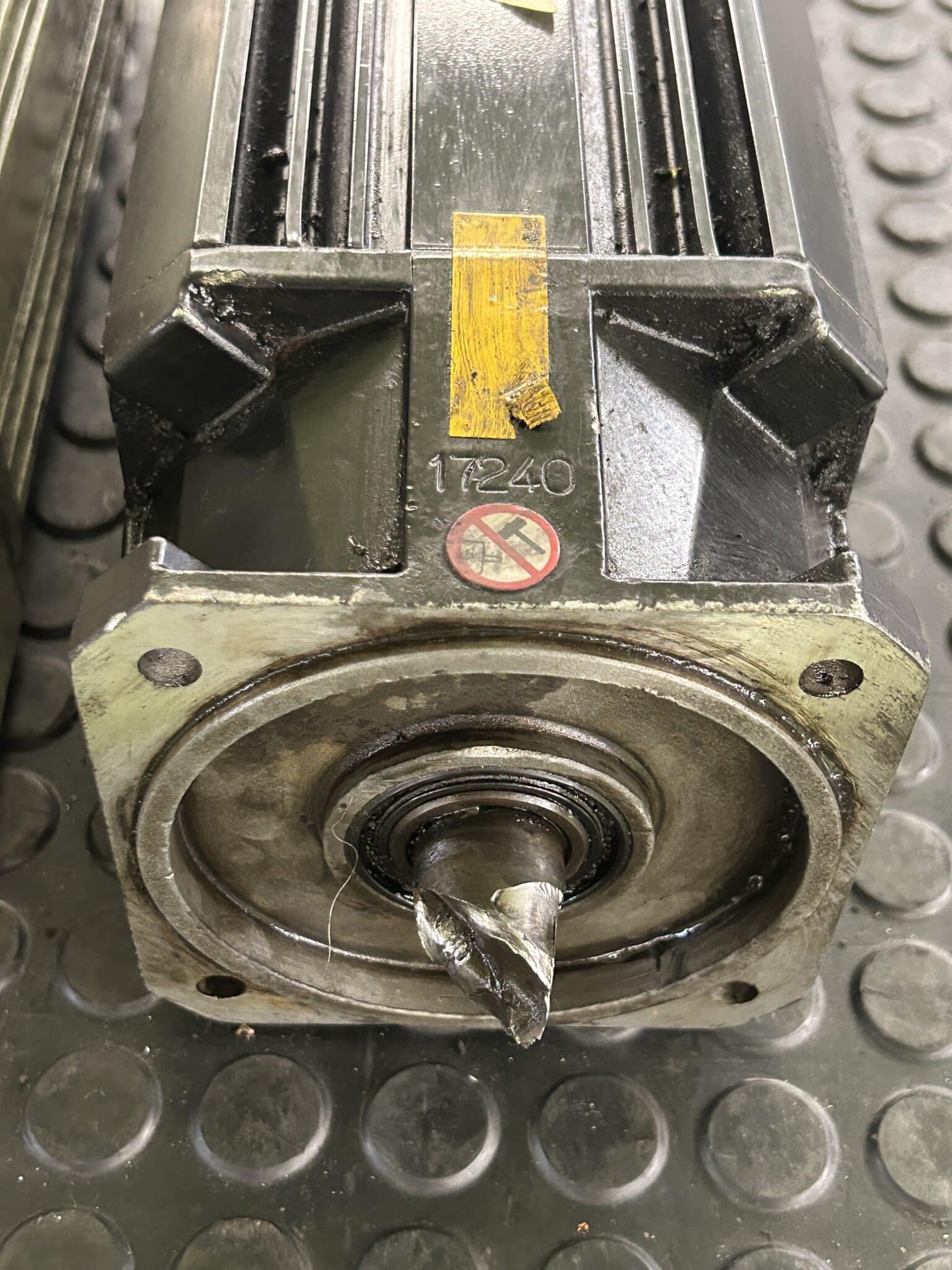

5. Sudden Stops or Faults in Drive System

-

Servo drives that lack proper deceleration profiles or safety braking mechanisms may induce shock torque.

-

Electrical faults causing uncontrolled motion or jamming can snap the shaft.

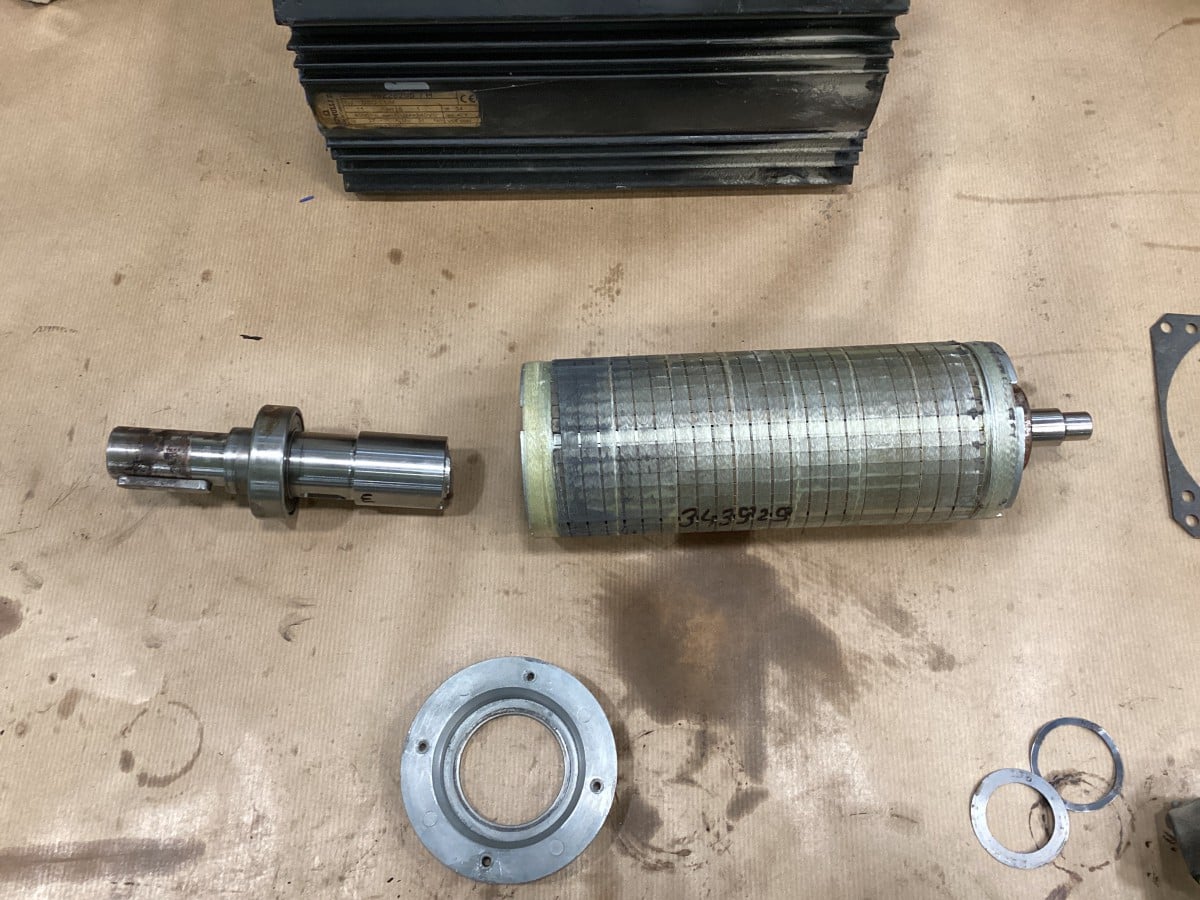

6. Poor Maintenance or Repair Practices

-

Reassembled incorrectly (e.g., improper bearing preload or excessive shaft loading).

-

Shaft damage during handling or bearing installation.

If you need a company specialising in servo motor repair, please do not hesitate to contact us.